OR-12 Slant CNC Lathe

A new standard in parts machining!

Applications

- Precision parts

- Precision nuts

- Watch parts

- Hand tools

Feature

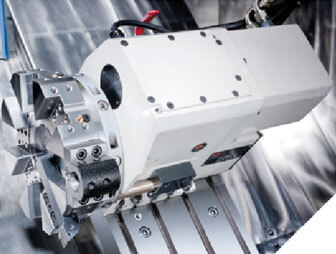

- 45˚ slant bed construction not only provides solld support for turret, but also provides convenience in chip removing.

- Ø42 mm bar capacity

- 4500 rpm, standard spindle speed

- 30m/min. rapid traverse on X, Z-axis

- Combines turret and gang-type tool rest in one machine

- The bed is manufactured from high quality Meehanite cast iron, and stress relieved to eliminate any deformation. Superior material stability and dampening capability ensure lifetime accuracy of the machine

- Precision linear way on X, Z-axis

- Foot switch controls chuck clamping/unclamping

- Automatic lubricator provides lubrication to X, Z-axes.

- Choice of Fanuc, Mitsubishi or Syntec CNC controller

- High performance hydraulic system features low thermal growth.

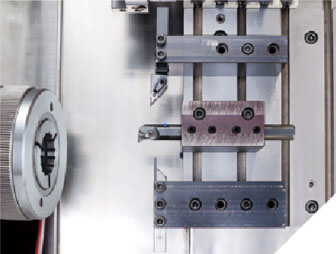

Gang-type Tool Rest

- The gang-type tool rest allows for the mounting of 6 tools.

- It accommodates a 20x20 mm tool shank andØ25 mm boring tool holder.

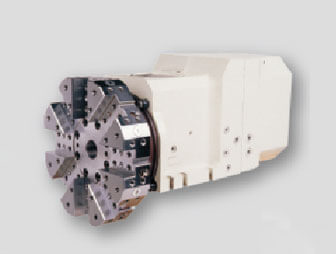

6" Hydraulic Chuck

- 6"Taiwanese-made hydraulic chuck comes as optional equipment.

- Japanese-made hydraulic chuck is optional.

- The hydraulic chuck is controlled by a foot switch.

a. Power Turret

- 12 tools

- Rapid tool indexing with smooth motion

b. Servo Turret

- Choice of 8 or 10 tools

- Rapid tool indexing, accurate positioning

8 / 10 / 12 Position Hydraulic Turret

- The hydraulic turret accommodates a 20x20 mm tool shank and Ø25 mm boring tool holder.

- Fast tool changes can be accomplished in 0.8 seconds.

Specifications

| Capacity | ||

|---|---|---|

| Swing over bed | Ø330 | |

| Swing over saddle | Gang-type Ø136 | Turret Ø135 |

| Standard cutting dia. . X length | Gang-type Ø135x200 | Turret Ø128x200 |

| Bed | ||

| Bed slant angle | 45˚ | |

| Max. travel X-axis | Gang-type 230 | Turret 150 |

| Max. travel Z-axis | Gang-type 230 | Turret 150 |

| Servo motor | X-axis 1.4 kw / Z-axis 1.4 kw | |

| Rapid traverse rate | X-axis 30m/min / Z-axis 30m/min | |

| Spindle | ||

| Front bearing hole of spindle | Ø90 | |

| Through-through spindle | Ø56 / Ø45 | |

| Spindle nose typ | A2-5 | |

| Spindle taper | MT-6 (1/20) | |

| Spindle motor | 5.5 / 7.5kw | |

| Spindle speed | 45-4500 rpm (Std.) / 60-6000 rpm (Opt.) | |

| Chuck size | Ø42 | |

| Turre | ||

| Type | Gang-type tool rest | Turret |

| Number of tools | 6 tools | 8-12 tools |

| Square tool shank sizes | 20x20 mm | 20x20 mm |

| Boring tool holder | Ø25 | Ø25 |

| Radial tool holder | 20x20 mm | 一 |

| Axial tool holde | 20x20 mm | 一 |

| Double tool holder | 20x20 mm | 一 |

| Motor | ||

| Turret motor | 一 | 1/4 HP |

| Coolant pump motor | 1/4 HP | |

| Hydraulic motor | 1 HP | |

| Chip conveyor motor | 1/4 HP | |

| CNC controller | ||

| Fanuc | Mitsubishi | Syntec |

| Miscellaneous | ||

| Distance from floor to spindle center | 900 | |

| Distance from bed to spindle center | 255 | |

| Machine dimensions (LxWxH) | 2120x1340x1550 | |

| Net weight | 2000 kg | |

| Gross weight | 2350 kg | |

*Specifications subject to change without notice.

Standard Accessories

- Spindle speed: 4500 rpm

- Spindle motor: 5.5 / 7.5 kw

- Gang type tool resst (20x20 mm)

- Leveling bolits and blocks

- Grease Iubrication system

- Control (Mitsubishi M70P)

- Service tools x 1 Set

- Work lamp

- Pilot lamp

- Collst chuck

- I.D. tool holder (20x20 mm)

- Parts catcher

Optional Accessories

- 6" hydraulic chuck

- Spindle speed: 6000 rpm

- Hydraulic turret (8-12 positions)

- Chip conveyor (with cart)

- Bar feeder

- Bar feeder control interface

- Oil mist collector

- Voltage stabilizer

- Leveling tooling furret (12 positions)

- Servo turret (8-12 positions)

- Soft jaw x1 Set/Hard jaw x1 Set

- Auto door

- External joint foot switch

- Start and stop the emergency switch